Tel. +49 (0) 7151.20534-0

info@smz-spindelservice.de

Definition through

performance and incentive

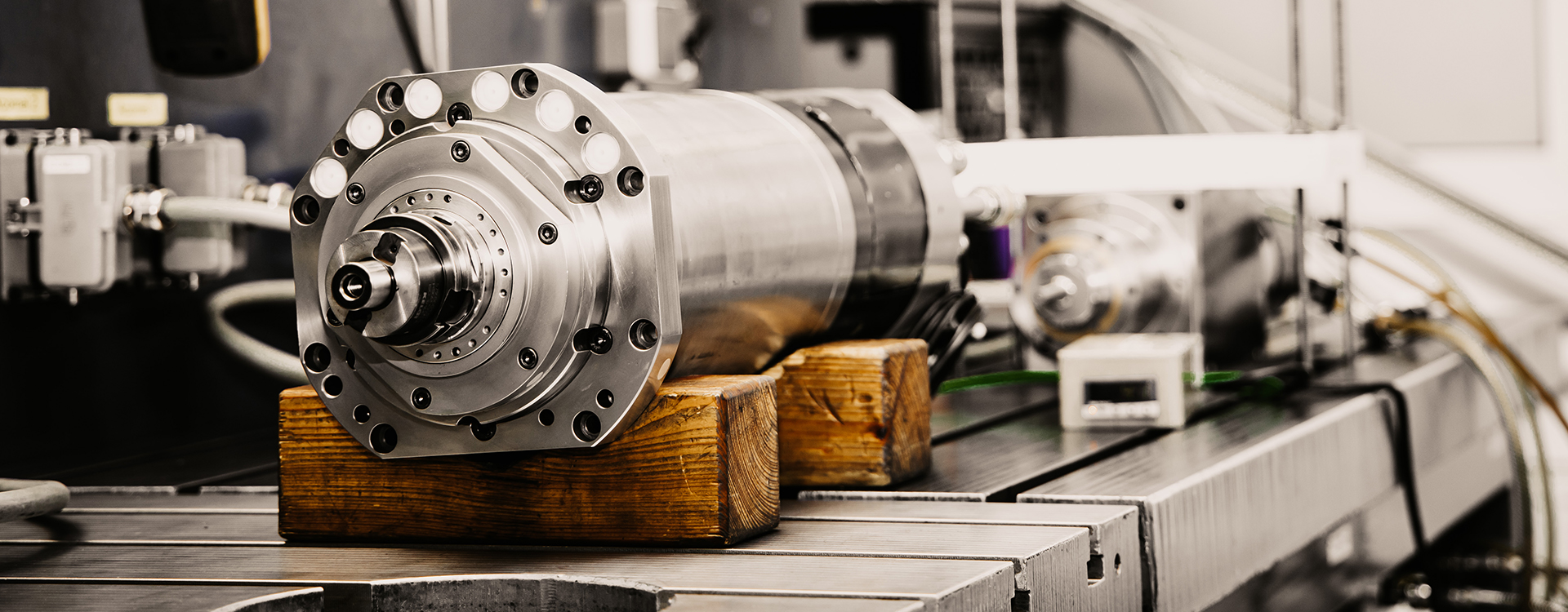

The heart of every machining centre, as well as of CNC, milling, grinding, turning and drilling machines, is the spindle. In order to help avoid possible production downtimes, we are at your disposal at any time to ensure that the spindle, and hence the machine, is quickly fully functional again – inexpensively and with a high standard of quality.

But the repair is only one aspect of our work. Our range of services also includes service and maintenance work.

Spindle service & spindle repair

System solutions for spindles

Spindle system optimisation

Spindle sales, on request

Spindle modifications

Vibration analyses

Maintenance contracts

Advisory service

Failure analyses

Drives with synchronous and asynchronous motors

Drives with belt drive and gear drive

Drives for spindles up to 180,000 rpm

Reconditioning of HSK and SK mounts

Reconditioning of bearing seats

Replacement of rotary encoders

Replacement of clamping sets and clamping systems

Maintenance training

Maintenance and repair of

all common spindle types

We carry out state-of-the-art maintenance and repair work for all common spindle types on the world market. In permanent, intensive cooperation with our customers, partners and suppliers, we are constantly expanding our skills and know-how. 30 years of experience cumulates in a perfect result. Guaranteed.

We repair spindles from the following manufacturers:

Blombach • Bridgeport • Capellini • Deuschle • DMG • Fadal • Faemat • Fischer • Fortuna • Gamfior • GMN • Grob • Heller • Henninger • HSD • HS-Tec • Ibag • IMT • Index • Jukomet • Jung • Kessler • Lidköpping • Mikron • Mori Seiki • Omlat • Precise • Reckerth • Renaud • Siemens • SKF • SLF • SNK • SPL • Steptec • Tacchella • Unior • UVA • Voumard • Weiss • and more

We repair the following types of spindle:

HF grinding spindles • HF drilling spindles • HF milling spindles with synchronous and asynchronous motors • Conventional internal grinding spindles • External grinding spindles • Surface grinding spindles • Main spindles of machining centres (motor, clutch and belt-driven) • Main spindles of lathes (motor, clutch and belt-driven)

Our 7-step all-inclusive service

IN 7 STEPS TO THE QUICK AND OPTIMUM SOLUTION OF YOUR PROBLEM.

Step 1

When the customer sends the spindle to SMZ, we enter it into our system database.

Step 2

During the incoming inspection, we check the spindle for all important features and components on our test bench. Here, the documented spindle is inspected for possible defects and then forwarded for disassembly.

Step 3

Our qualified personnel carry out the disassembly of the spindle, including an inspection of the electrical components, measurement of the individual parts, fault analysis and preparation of a repair report.

Step 4

The customer receives a detailed cost estimate.

Step 5

Once the customer has approved the cost estimate, assembly of the spindle with all its individual parts and spare parts begins. Cleaning of the spare parts and dynamic balancing of the spindle shafts (balancing quality G=2.5) is another important part of this step.

Step 6

When the repair has been completed, a fully automatic test run is carried out with measurements and monitoring of temperatures, lubrication, speed and vibration.

Step 7

The last step is the careful final inspection, where we attach particular importance to quality and accuracy. The results are entered into our system database as well as being handed over to the customer in the form of a test report.